Máquina De Papel Fourdrinier

Preço do produto

Preço sob consulta

Informações sobre pagamento e envio

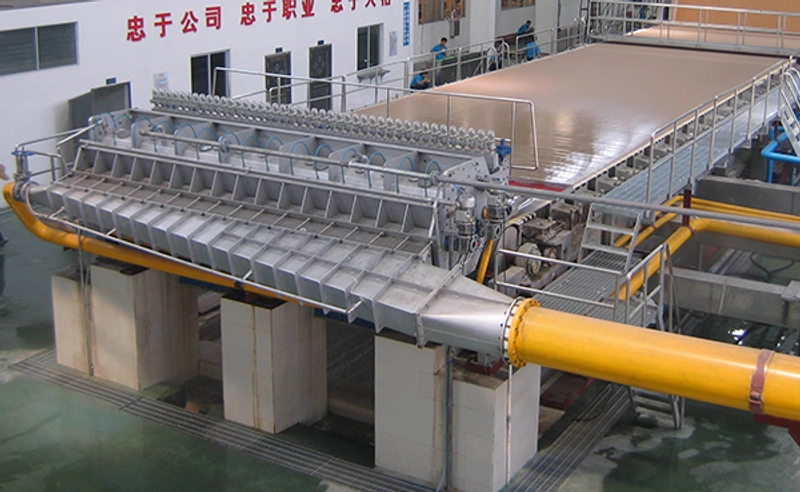

Máquina De Papel Fourdrinier

Henan Jinzeyuan Mechannical Equipment Co.,Ltd

Detalhes do produto

Muitas máquinas de fabricação de papel são baseadas nos princípios da Máquina de Papel Fourdrinier, que usa uma correia transportadora de malha de tecido plástico especialmente tecida na seção de moldagem, onde uma pasta de fibra (geralmente madeira ou outras fibras vegetais) é drenada para criar uma teia de papel contínua. Após a seção de formação, a teia úmida passa por uma seção de prensa para espremer o excesso de água e, em seguida, a teia prensada passa por uma seção de secagem aquecida. A máquina de papel Fourdrinier tem quatro seções operacionais distintas: A seção de formação, comumente chamada de extremidade úmida, é onde a pasta de fibras filtra o fluido em um laço contínuo de tecido para formar uma teia úmida de fibra. Seção de prensa onde a teia de fibra úmida passa entre grandes rolos carregados sob alta pressão para espremer o máximo de água possível. Seção de secagem, onde a chapa prensada passa parcialmente ao redor, de forma serpentina, de uma série de cilindros de secagem aquecidos a vapor. A secagem remove o teor de água até um nível de cerca de 6%, onde permanecerá em condições atmosféricas internas típicas. Seção de calandra onde o papel seco é alisado sob alta carga e pressão. Apenas uma pinça é necessária para segurar a chapa, que encolhe na seção de secagem e é mantida em tensão entre a seção da prensa (ou pilha de disjuntores, se usada) e a calandra. Pinças extras proporcionam mais suavização, mas prejudicam a resistência do papel.

Sobre o fornecedor

Visite a página do fornecedorFornecedor de contato

Mais produtos do fornecedor

Produto similar

Máquina Fourdrinie...

Fabricante líder de máquinas de papel na China, equip...

Henan Jinzeyuan M...

Máquina de escreve...

Papéis para impressão e escrita são tipos de papel us...

Henan Jinzeyuan M...

Bomba de ventilado...

A bomba do ventilador impulsiona a pasta diluída da m...

Henan Jinzeyuan M...

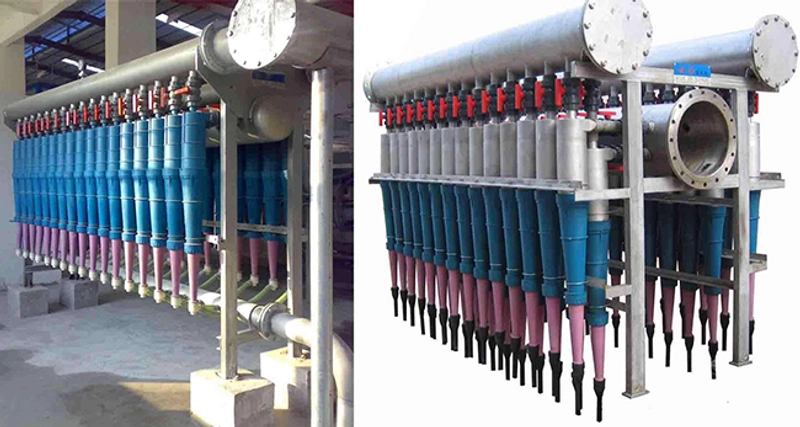

Limpador de alta d...

O limpador de baixa densidade (limpador centrífugo) é...

Henan Jinzeyuan M...

Peneira vibratória...

O separador de fibra é um equipamento de desfibra de ...

Henan Jinzeyuan M...

Filtro de disco De...

Uma nova geração de equipamentos de recuperação de ág...

Henan Jinzeyuan M...

Tela de pressão, e...

A tela de pressão pertence ao equipamento de triagem ...

Henan Jinzeyuan M...

Despolpador hidráu...

Despolpador hidráulico de alta consistência para fabr...

Henan Jinzeyuan M...

Máquina de fazer r...

Estrutura principal da seção de fabricação de papel (...

Henan Jinzeyuan M...

Papel usado para r...

Reciclagem de resíduos de papel ondulado, estrutura d...

Henan Jinzeyuan M...