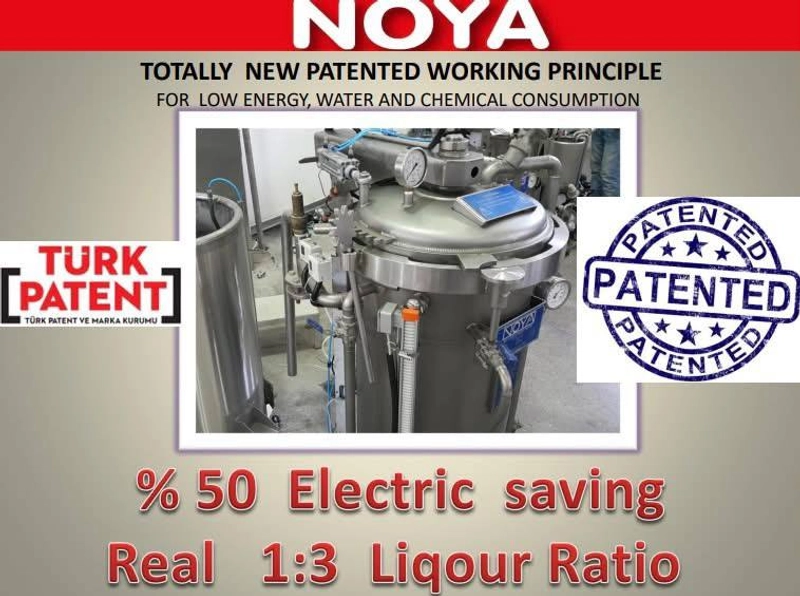

Máquina De Tingimento De Fios (SISTEMA PATENTEADO)

Preço do produto

Preço sob consulta

Informações sobre pagamento e envio

Máquina De Tingimento De Fios (SISTEMA PATENTEADO)

Noya Mekatronik

Detalhes do produto

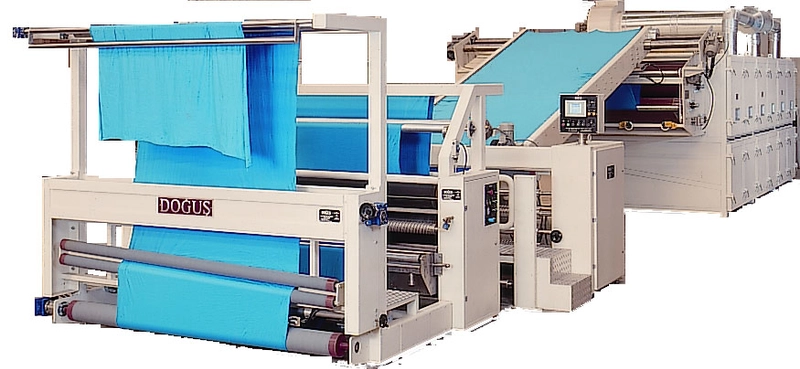

A máquina de tingimento de fios HT é projetada com base nas mais recentes melhorias técnicas e tecnológicas em relação a; fluxo de licor, circulação de licor e máxima eficiência. A máquina pode ser usada para o processamento de muitos tipos diferentes de materiais com o uso de diferentes suportes adequados, como embalagens de bobinas, protetores, vigas, material solto, tampas, etc.

Especificação

TECHNICAL ADVANTAGES Perfect dyeing results without having unlevelled dyeing effect for max. 2 kg bobbins in weight. Inside/outside and outside/inside two way flow without changing the direction of the snail pump motor. Short and fast heating times by efficient heat exchanger Dyeing capacity of min 50% and max. 100% with air pad system Perfect dyeing possibility on every pressure with differential pressure transmitter Repeatability by automation system Short dyeing times with the help of 100% reserve tank Liquor ratio in between 1:5 - 1:8 Single or double material carrier Heat exchanger in the circulation pipe line Rapid lid opening, closing, locking system Heavy duty stainless steel centrifugal pump with mechanical seal. DRYING PROCESS CONSISTS OF 3 SEQUENCES; HYDROEXTRACTION: replaces centrifugal operation and is done directly after loading of wet yarn carrier coming from dyeing machine. DRYING: Drying process starts automatically alter hydroextraction. The air is blown by the blower through heat exchanger for heating, heated at preset temperature according to yarn type and colour shade, flows at high speed through the yarn 1/0 direction, thereby transferring heat to the yarn and saturating with evaporated water. Duration of drying phase is preset on the base of air temperature at inlet and outlet of yarn packages 3 - YARN CONDITIONING: After the drying phase, air is circulated O/l direction in order to equalize residual humidity in yarn packages and reduce the temperature of the yarn. ADVANTAGES: No need of centrifuge hydro extractor. Loading and unloading is the waste time and also yarn packages may be damaged during loading /unloading. Process time is 50% to 70% shorter due to closed loop. Labour is dramatically reduced in the whole drying process.

Porto de embarque

Turquia

Izmir Port

Sobre o fornecedor

Visite a página do fornecedorFornecedor de contato

Mais produtos do fornecedor

Produto similar

Máquina de costura...

Juki MF-7923 é uma máquina de costura industrial de 3...

Go Sewing Store

Máquina de costura...

A máquina de costura Feed Dog é um componente chave q...

M/S MAKALI MANUFA...

Dentes de máquina ...

Os dentes da máquina de costura, também conhecidos co...

M/S MAKALI MANUFA...

Anel de corrida pa...

O anel de corrida da máquina de costura é um componen...

M/S MAKALI MANUFA...

Suporte de máquina...

O suporte da máquina de costura é uma peça de suporte...

M/S MAKALI MANUFA...

Repair Loom Easy M...

Operação estável, manutenção conveniente, baixo ruído...

Jiangxi Zhongbo I...

Máquina de tecelag...

Modo de acionamento: acionamento direto do motor de r...

Jiangxi Zhongbo I...

Tear de rapier de ...

Tear jacquard de alta velocidade ZBMAX98J: uma escolh...

Jiangxi Zhongbo I...

ZBGTMAX Towel Weav...

Tear de tecelagem a jato de ar com toalha felpuda de ...

Jiangxi Zhongbo I...

Modelo Zbmax88-600...

O tear de florete de alta velocidade de largura larga...

Jiangxi Zhongbo I...